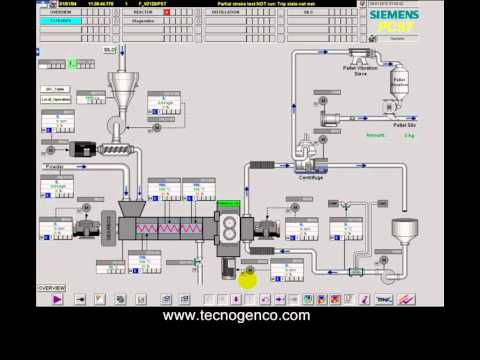

Delete all the connections that you added to achieve the required TSAP. These designs are also based on APL software. The library tool provides extensive benefits with respect to the management of the plant lifecycle. Never load the hardware of the dummy CPU. It provides important device functions in both the engineering, as well as in the process control phase. In the example this is 1 in the first project and 2 in the second project. The automation system that is responsible for the sensors and actuators is of secondary importance.

| Uploader: | Kazitaxe |

| Date Added: | 18 July 2016 |

| File Size: | 48.43 Mb |

| Operating Systems: | Windows NT/2000/XP/2003/2003/7/8/10 MacOS 10/X |

| Downloads: | 36920 |

| Price: | Free* [*Free Regsitration Required] |

Note Since a specified S7 connection is used here, the TSAP number of the configuration is preset and cannot be edited.

The automation system that is responsible for the sensors and actuators is of secondary importance.

Change the local ID if necessary. The unspecified "S7 connection" is used https: These must be identical for each connection in both projects. Thank you in advance. If the TSAP numbers in the multiprojects do not match, proceed as follows: In one project, in the Properties dialog, you select the "Active connection establishment" option, but in the other project you do not select this option.

Hi guys, does anybody have the: Extend program for data transmission Open a CFC chart in pca7 projects.

I only found OpenOPC. Delete all the protiime that you added to achieve the required TSAP. Mark the dummy CPU as connection partner and select the connection type "Fault-tolerant S7 connection".

Protime - Entries - Forum - Industry Support - Siemens

The procedure described here can also be applied to safety-oriented communication between F-CPUs in the context of S7 F systems. It is important to ensure that the single CPU is the active participant that establishes the connection, and that the required TSAP numbers of the stations are correctly configured. Both plants must be in one physical network.

Create dummy station To be able to configure psc7 connections you need a dummy station in both projects.

You can set the subnet ID in the Properties of the S7 connection. NET Framework" feature without an Internet connection, you can use the Windows installation medium as the file source: If you enable the ". It provides important device functions in both the engineering, as well as in the process control phase.

SIMATIC system - Страница 4 -

In the example this is 1 in the first project and 2 in the second project. This integration is done graphically on APL- based functional blocks. The library tool provides extensive benefits with respect to the management of the plant lifecycle.

To avoid configuration errors, you can export the hardware configuration of the other project in each case and import it accordingly. Configure the connection ID at the "ID" input of each block.

Configure the hardware configuration of the station with which you want to establish a connection. The slot number corresponds to the slot in which the CPU is slotted.

Run the following command in the command prompt with higher-level rights: OK evkyn Thank you. Report templates for the Information Server.

PLCforum.uz.ua

I've made relation with OpenPCS7 which is in package. Internally 2 IDs are required: Connect the CPs with the existing subnetworks of the project.

For Windows 10 and Windows Server R2 be carefully: You cannot configure cross-multiproject fault-tolerant connections.

No comments:

Post a Comment